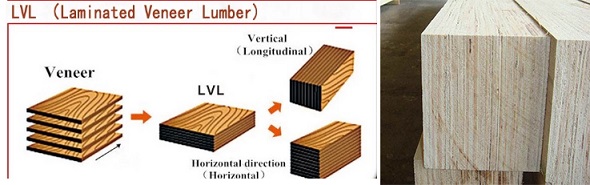

LVL (Laminated Veneer Lumber) is a board made of raw wood by rotary cutting or planing. After drying and gluing, it is formed by gluing along the grain or most of the grain, and then gluing by hot pressing.

Product material: poplar, pine

Product use: furniture grade lvl, door core material, lvl for pillars, fumigation-free packaging boxes, fumigation-free trays, other transportation packaging uses. This product is used for packaging of large-scale machinery and equipment. It has greater strength than solid wood, uniform strength, and has the advantages of no fumigation and low cost. It is especially suitable for various types of transport packaging materials. LVL is mainly used for various packaging plants, wood products factories, and furniture Factories, construction sites, etc., especially the export packaging of machinery, glass, chemicals, etc.; wooden keels for furniture such as sofas, wooden keels for sports facilities, wooden keels for floors; footboards for construction, I-beams, etc. It is used in container sills, building formwork components, building beams, carriage panels, room decoration wood keels, etc.

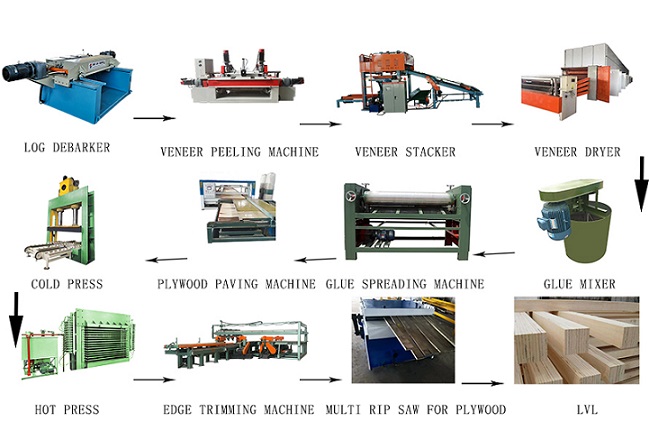

First, use a veneer making machine to cut the logs into veneers of specifications. After drying the veneers with a dryer, then glue and age the contact surfaces of the veneers with a glue applicator; tile the aged veneers layer by layer. Pre-press by cold press, hot press by hot press, final division, chamfering, anti-corrosion.

Hig Strength

As the LVL is made of veneers which are cut by rotary cutting machine and assembled with adhesives through hot-pressing therefore , it can reduce the influence of strength defects.

Low cost

LVL production could use small diameter wood,ben wood and short logs,therefore the output rate could reach 60% to 70%. In other words, LVL could produce value-added effect by using small material.

Flexible sizes

For special manufacturing method , the sizes of the LVL is not limited by the sizes of the logs or the veneers , so the sizes is flexible, can be freely chosen .

Contact: Peter Gong

Phone: 0086-18669671318

Tel: 0086-539-8390323

Email: info@veneermachine.com

Add: A4-3-101 HUIGU RORAL HEDONG,LINYI CITY,SHANDONG PROVINCE,P.R.CHINA